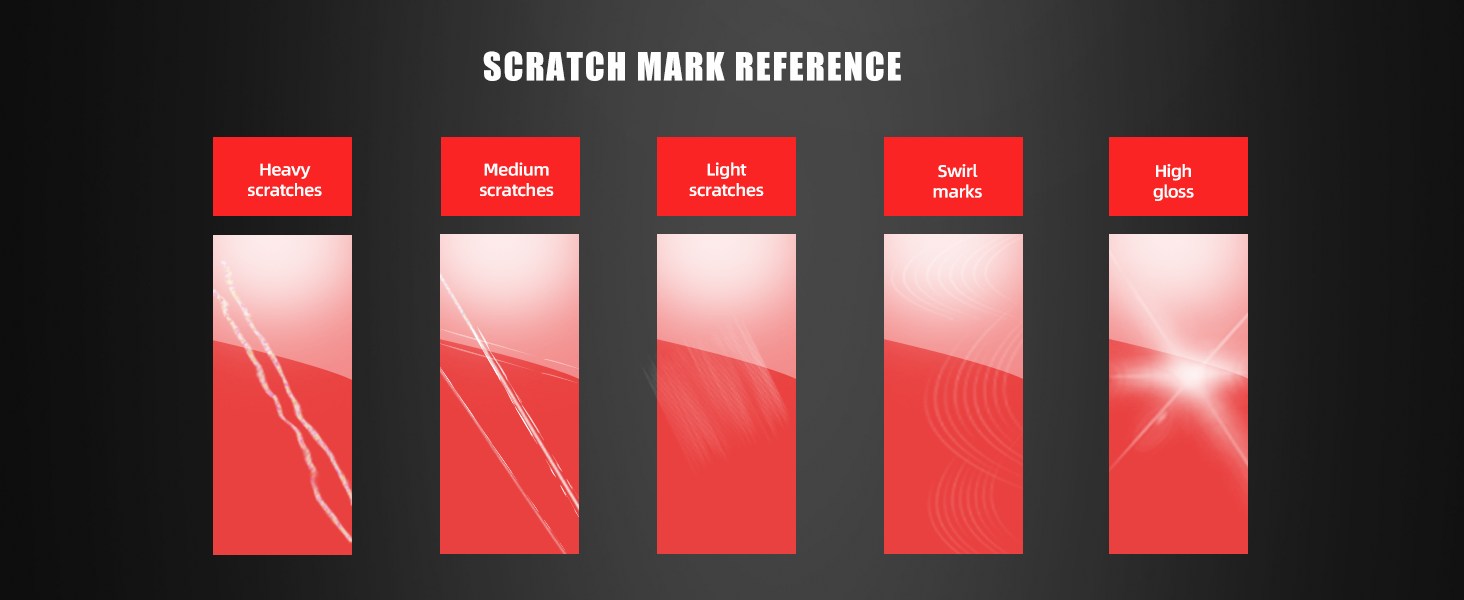

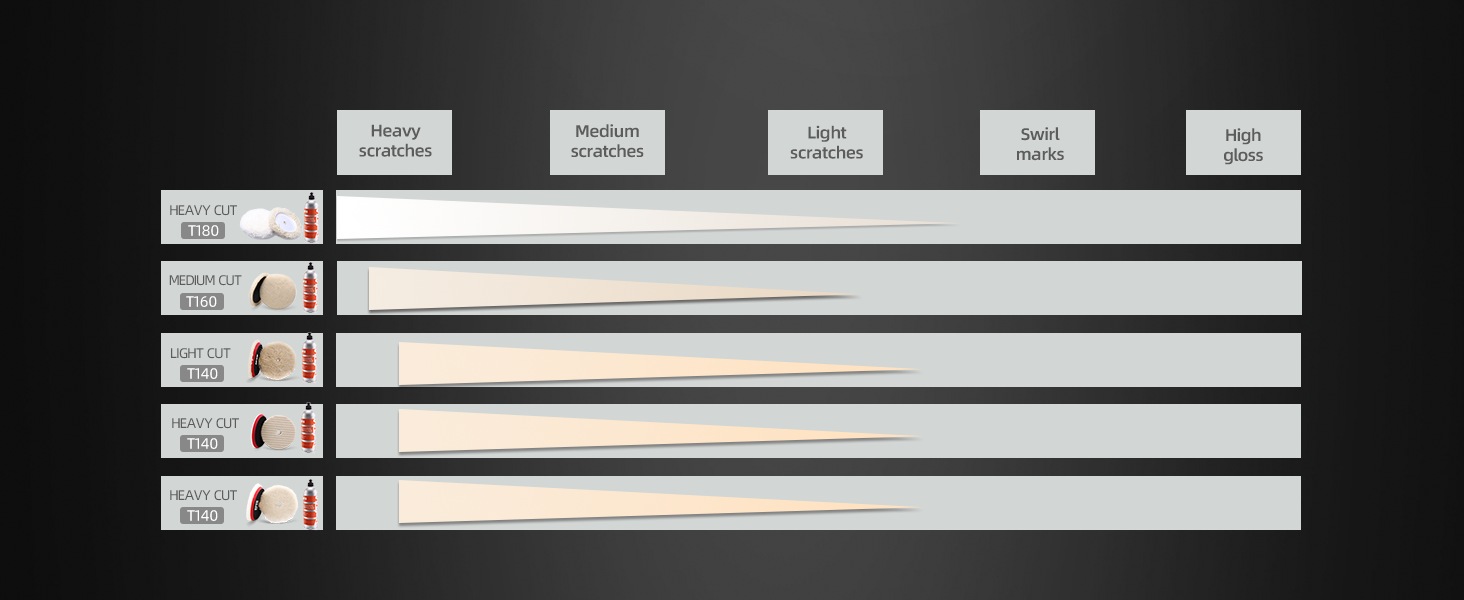

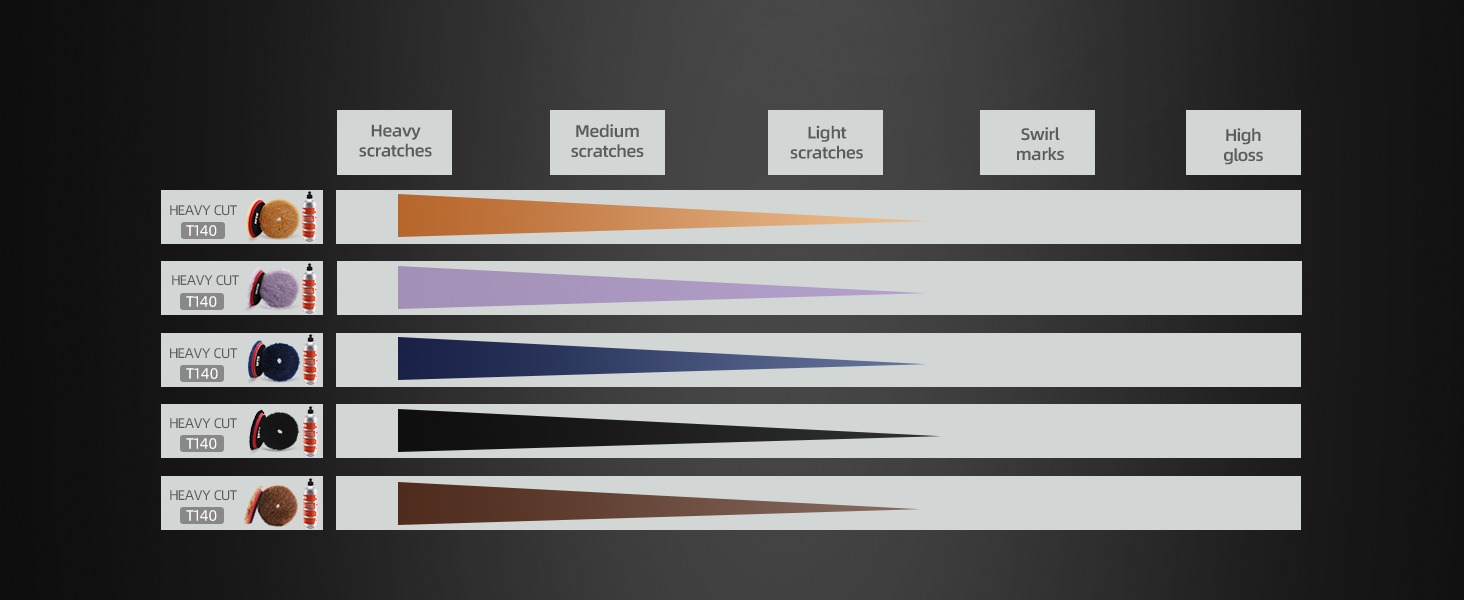

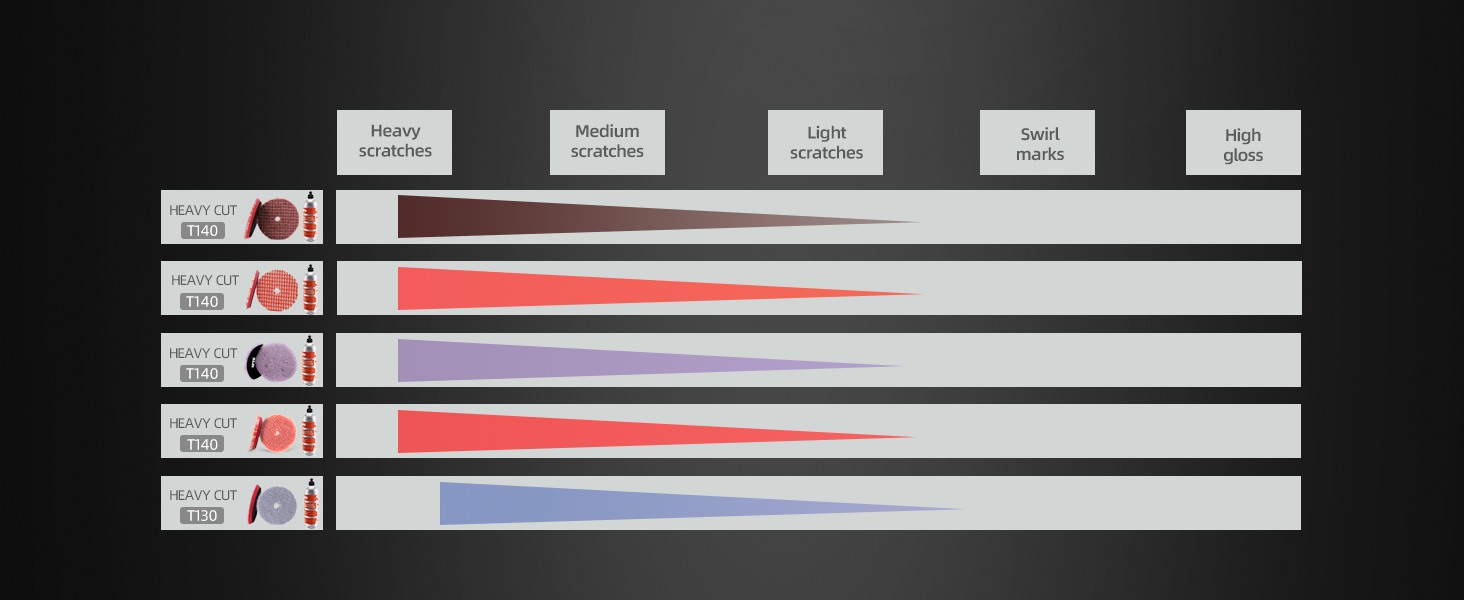

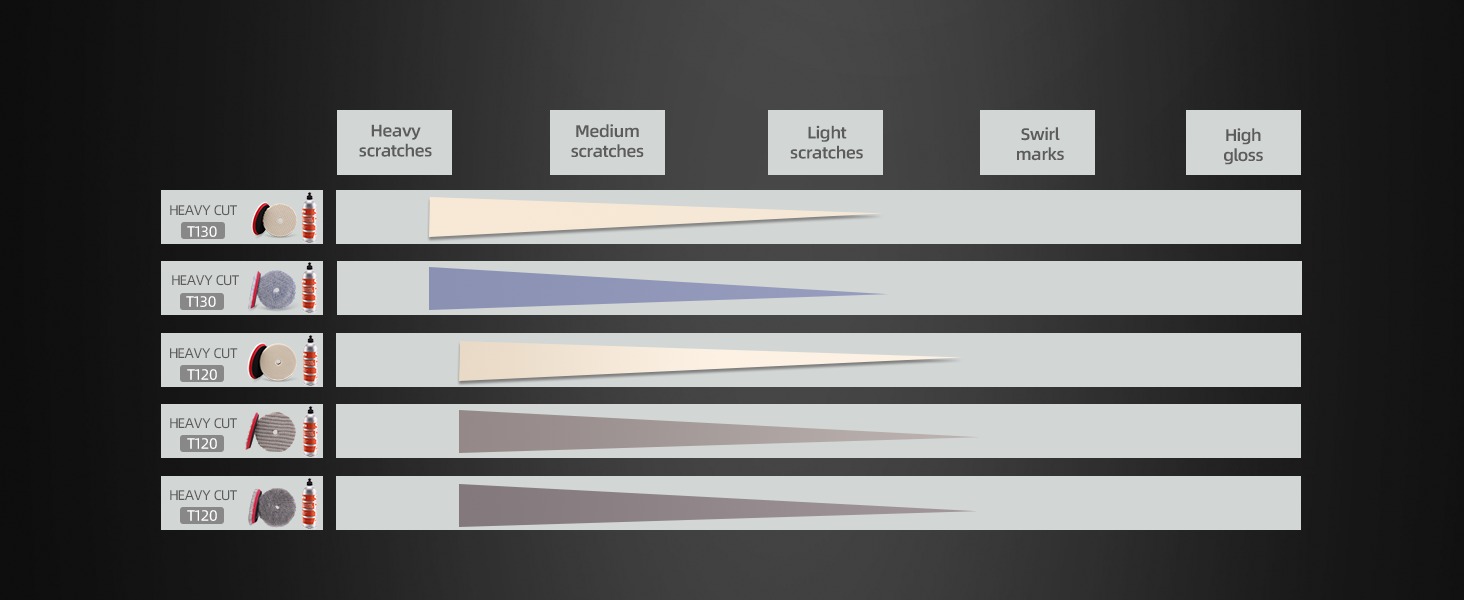

SPTA 3"/5"/6" Wool Polishing Pad, T140 Brown Heavy Cut Wool Pad to Remove 1200#/1500# Sanding Disc Marks, Deep Scratches, Orange Peel and Heavy Oxidation for Automotive, Car, RV, Motorbike & Boat

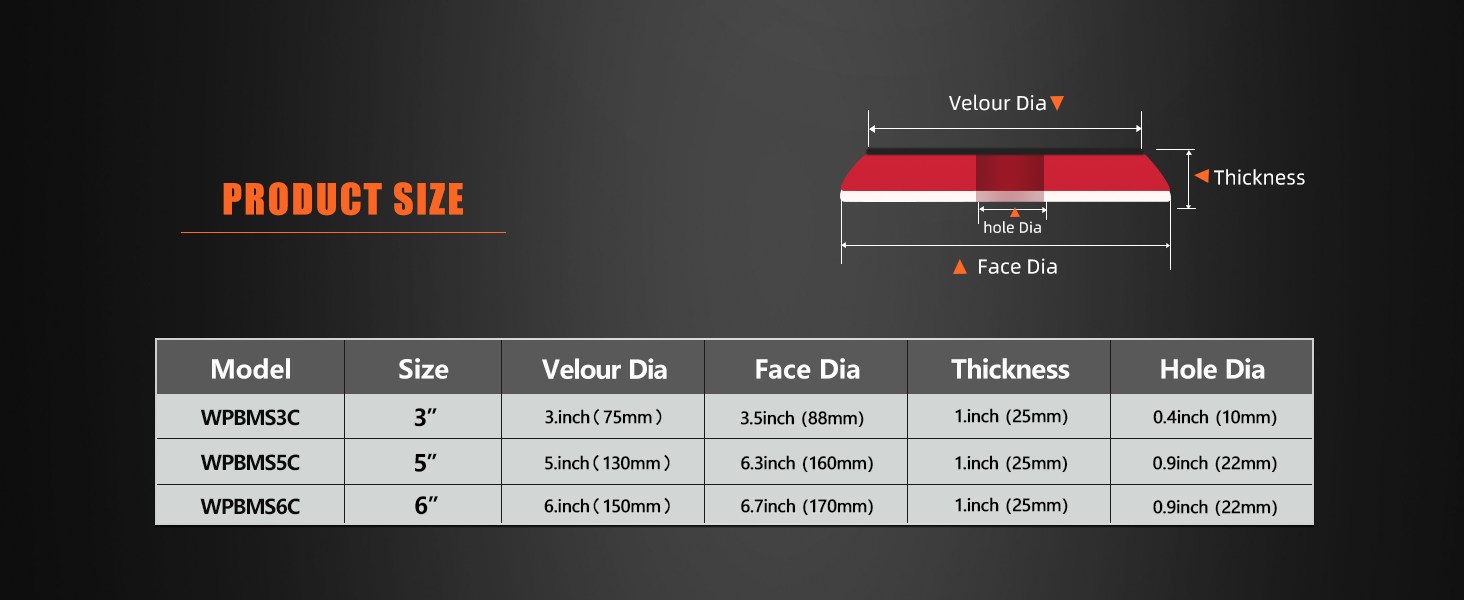

Item No.: WPBMS3C/WPBMS5C/WPBMS6C

Available Size : 3"(80mm)/5"(125mm)/6"(150mm)

Apply for both rotary and dual action car polishers

Polybag packing for each product

Samples and OEM accepted

SKU: WPBMS3C/WPBMS5C/WPBMS6C